Explore Case Studies

MODAPTS® is an easy and effective method to measure productivity. A tool for

analyzing human work, MODAPTS® helps you determine reasonable expectations for the time

required to complete a defined task by a trained operator.

analyzing human work, MODAPTS® helps you determine reasonable expectations for the time

required to complete a defined task by a trained operator.

MODAPTS® is an easy and effective method to measure productivity. A tool for analyzing

human work, MODAPTS® helps you determine reasonable expectations for the time required to complete a defined task by a trained operator.

Optimizing Engine Assembly

Line Using MODAPTS®

Optimizing Engine Assembly Line Using MODAPTS®

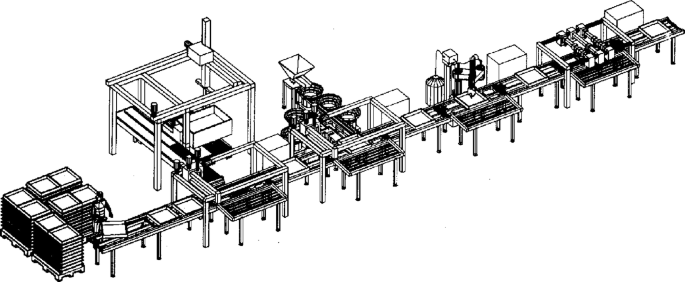

In early 2008, the engine assembly plant faced rising demand, fluctuating production volumes, and workforce challenges. To address these issues, the management adopted MODAPTS (Modular Arrangement of Predetermined Time Standards) as a systematic approach to measure work, rebalance the line, and optimize resources. This case study documents the plant’s journey across three major rebalancing initiatives, the challenges faced, and the measurable impact on efficiency, productivity, and workforce allocation.

Years of Experience

0

+

Certified Engineers

0

+

Happy Clients

0

+

- Jan 08 - May 08

Current State of Engine Assembly Line

Intial audit revealed the following performance metrics.

- Jobs per Hour (JPH) : 164

- Hours per Unit (HPU): 4.59

- Cycle time per operation in seconds: 22

- Operators: 129

- Key Finding: Audit of existing MODAPTS studies revield changes to assembly process had not been updated.

- Outcome: MODAPTS studies updated to reflect current state.

- Sept 08 - Nov 08

Assembly line rebalance #1

Line speed incread and assenbly line was rebalanced to meet increased demand .

- Jobs per Hour (JPH) : 200

- Hours per Unit (HPU): 4.57

- Cycle time per operation in seconds: 18

- Operators: 32

- Key Action: Line speed increased. (3) operators added.

- Outcome: Plant successfully scaled output to meet demands without compromising Quality and efficciently

- Jan 09 - May 09

Assembly line rebalance #2

Line speed decreased to meet demand levels.

- Jobs per Hour (JPH) : 120

- Hours per Unit (HPU): 5.03

- Cycle time per operation in seconds: 30

- Operators: 90

- Key Action: Line speed decreased. (42) operators rebalanced of the assembly line.

- Outcome: Assembly line processes were optimized to match demand aligning output with lower throughtput.

- Jun 09 - Jun 09

Assembly line rebalance #3

Line speed incread and assenbly line was rebalanced to meet increased demand .

- Jobs per Hour (JPH) : 164

- Hours per Unit (HPU): 4.41

- Cycle time per operation in seconds: 22

- Operators: 99

- Outcome: 3 assembly line rebalances within 10 months.

- Same amount of engines produced requiring: 23% less direct labor 4% decrease in HPU (Hours per Unit)

- Jan 08 - May 08

Current State of Engine Assembly Line

Intial audit revealed the following performance metrics.

- Jobs per Hour (JPH) : 164

- Hours per Unit (HPU): 4.59

- Cycle time per operation in seconds: 22

- Operators: 129

- Key Finding: Audit of existing MODAPTS studies revield changes to assembly process had not been updated.

- Outcome: MODAPTS studies updated to reflect current state.

- Sept 08 - Nov 08

Assembly line rebalance #1

Line speed incread and assenbly line was rebalanced to meet increased demand .

- Jobs per Hour (JPH) : 200

- Hours per Unit (HPU): 4.57

- Cycle time per operation in seconds: 18

- Operators: 32

- Key Action: Line speed increased. (3) operators added.

- Outcome: Plant successfully scaled output to meet demands without compromising Quality and efficciently

- Jan 09 - May 09

Assembly line rebalance #2

Line speed decreased to meet demand levels.

- Jobs per Hour (JPH) : 120

- Hours per Unit (HPU): 5.03

- Cycle time per operation in seconds: 30

- Operators: 90

- Key Action: Line speed decreased. (42) operators rebalanced of the assembly line.

- Outcome: Assembly line processes were optimized to match demand aligning output with lower throughtput.

- Jun 09 - Jun 09

Assembly line rebalance #3

Line speed incread and assenbly line was rebalanced to meet increased demand .

- Jobs per Hour (JPH) : 164

- Hours per Unit (HPU): 4.41

- Cycle time per operation in seconds: 22

- Operators: 99

- Outcome: 3 assembly line rebalances within 10 months.

- Same amount of engines produced requiring: 23% less direct labor 4% decrease in HPU (Hours per Unit)

MODAPTS® Results & Conclusion

Over 18 months, the assembly line demonstrated the adaptability and effectiveness of MODAPTS®-driven rebalancing:

- Increased maximum throughput from 164 JPH to 200 JPH (Rebalance #1).

- Maintained operational flexibility by reducing workforce from 132 to 90 operators during downturns.

- Optimized plant HPU across fluctuating demands, showing that efficiency was not compromised despite scaling up or down.

- Proved the value of data-driven rebalancing in maintaining both cost-effectiveness and output reliability.

The case of the engine assembly line highlights the importance of dynamic workforce planning and line balancing using MODAPTS®. By responding to shifts in demand with strategic rebalances, the plant was able to maintain operational agility, ensure cost efficiency, and meet customer needs. This approach provides a replicable framework for other manufacturing facilities seeking to optimize their assembly lines in volatile markets.