A Guide to Staffing Model Development

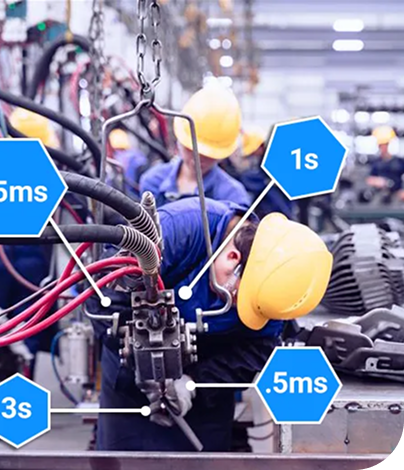

Staffing Model Development Guide: By creating and using a staffing model, a small business can maximize efficiency by ensuring it is staffed with the right number of people, possessing the relevant skill sets to meet critical business needs at the appropriate time. 1) Begin with Right Number of People Identify all critical skills and define each job role needed to properly staff the company. Develop a baseline staffing level, or standard. This is made up of staff members whose absence has a significant impact on core functions within the business. 2) Possess the Relevant Skill Sets Identify any critical gaps within the organization. Determine when and where critical needs exist that aren’t being met by current staffing levels. Examine if any additional skill-sets are needed that are not currently possessed by any current employee. Assess these gaps to be filled with internal actions such as transfers or cross training. Cross training is a very effective way of developing talent from within. Determine if external recruitment efforts will be needed. 3) Forecasting Growth Forecast your future organizational needs. Review your goals, mission statement and strategic plan to develop a sound staffing model for your small business. Identify any areas where the company is expected to grow in the near future. Consider any planned expansion such as new product lines, new customers or market segments and any potential acquisition of competitors. Identify the additional staffing or skill sets needed to achieve this growth. Utilize your staffing model to identify any additional positions that will increase a permanent base for your staffing levels. Identify any temporary gaps to address a defined short-term need. 4) Plan for the Unexpected – Cross Training Staff Account for absences. This includes those that can be controlled — such as terminations – and those which cannot be controlled, like medical leave. Show in the staffing model your retirement-eligible staff – determine if there are actions that can be taken to train other staff to replace those duties. Especially when retirements occur or when your business needs to hire from the outside. 5) Recruitment for Hard-to-Find Skills Develop a recruitment plan to quickly solve any staffing issues that can’t be dealt with through internal training or succession planning. Know when recruitment is required in order to keep essential staff on board at all times. If you are recruiting staff with hard-to-find skills, it might be wise to have an open recruitment. Hiring staff members whenever you can find someone suitable — even if no gap exists — will help you to be sure you have appropriately-skilled individuals any time you need them. Document all staffing model plans in writing. Also, remember to adjust them as changes to your business plan take place. Utilization of Predetermined Time Standards in Staffing Model Development Accurate staffing is particularly important in a small business, because many positions can represent a single point of failure. In a large business, holes in staffing can be compensated for in other areas. Over-staffing can be absorbed until attrition occurs. However, this is not always the case in a small business – where a single staff member represents a significant percentage of your total employees. To this end, many businesses are choosing to apply modular arrangements of predetermined time standards (MODAPTS) to position development and task performance consistency for better direct labor staffing model applications. Are you interested in learning more about how predetermined systems can be used to train and teach your employees? If so, contact us for more information. We have helped others, maybe we can help you too.